Quality Standards for Power Bank Manufacturing: Export Certifications Guide

Why Quality Matters in Power Bank Export

Exporting power banks requires strict quality standards. Poor quality can damage your reputation and create legal issues. Customers expect safe, reliable products that meet international standards.

The Cost of Poor Quality

Low-quality power banks can cause:

- Device damage from voltage spikes

- Fire hazards from battery failures

- Legal liability in international markets

- Brand reputation damage

- Customer refund claims

Quality standards protect your business and customers.

Key International Certifications

CE Marking (European Union)

What is CE Marking? CE marking shows your power bank meets EU safety standards. Without CE marking, you cannot sell in Europe.

CE Requirements for Power Banks:

- EMC Directive (electromagnetic compatibility)

- Low Voltage Directive (electrical safety)

- RoHS Directive (restricted substances)

- RED Directive (radio equipment)

Testing Process:

- Product testing by approved labs

- Technical documentation preparation

- Declaration of conformity

- CE marking application

Timeline: 4-8 weeks Cost: $5,000-15,000

FCC Certification (United States)

FCC Requirements All electronic devices sold in the US need FCC approval. Power banks require FCC ID certification.

Testing Categories:

- Electromagnetic interference (EMI)

- Radio frequency emissions

- SAR testing (if wireless features)

- Intentional radiator testing

Process Steps:

- Apply for FCC ID

- Submit test reports

- Provide user manuals

- Pay application fees

Timeline: 6-10 weeks Cost: $3,000-10,000

UL Certification (North America)

UL 2089 Standard UL 2089 covers health and safety for portable power banks. This certification builds customer trust.

Testing Areas:

- Battery safety

- Charging circuit protection

- Thermal testing

- Mechanical stress testing

Benefits:

- Higher retail acceptance

- Insurance coverage

- Consumer confidence

- Reduced liability

CB Scheme (Global)

International Recognition CB certification is accepted in 50+ countries. One test report opens multiple markets.

CB Advantages:

- Cost-effective for multiple markets

- Recognized by major countries

- Streamlined approval process

- Single test laboratory

Battery Safety Standards

UN 38.3 Transportation Testing

Mandatory for Shipping All lithium batteries must pass UN 38.3 tests before international shipping.

Test Requirements:

- Altitude simulation

- Thermal testing

- Vibration testing

- Shock testing

- External short circuit

- Impact testing

- Overcharge testing

- Forced discharge

Documentation Needed:

- Test summary

- Transport classification

- Packing instructions

- Emergency response procedures

IEC 62133 Battery Safety

Scope of Testing IEC 62133 covers battery safety for portable applications.

Key Tests:

- Continuous low-rate charging

- Molded case stress

- Drop test

- Thermal abuse

- Overcharge protection

- Short circuit testing

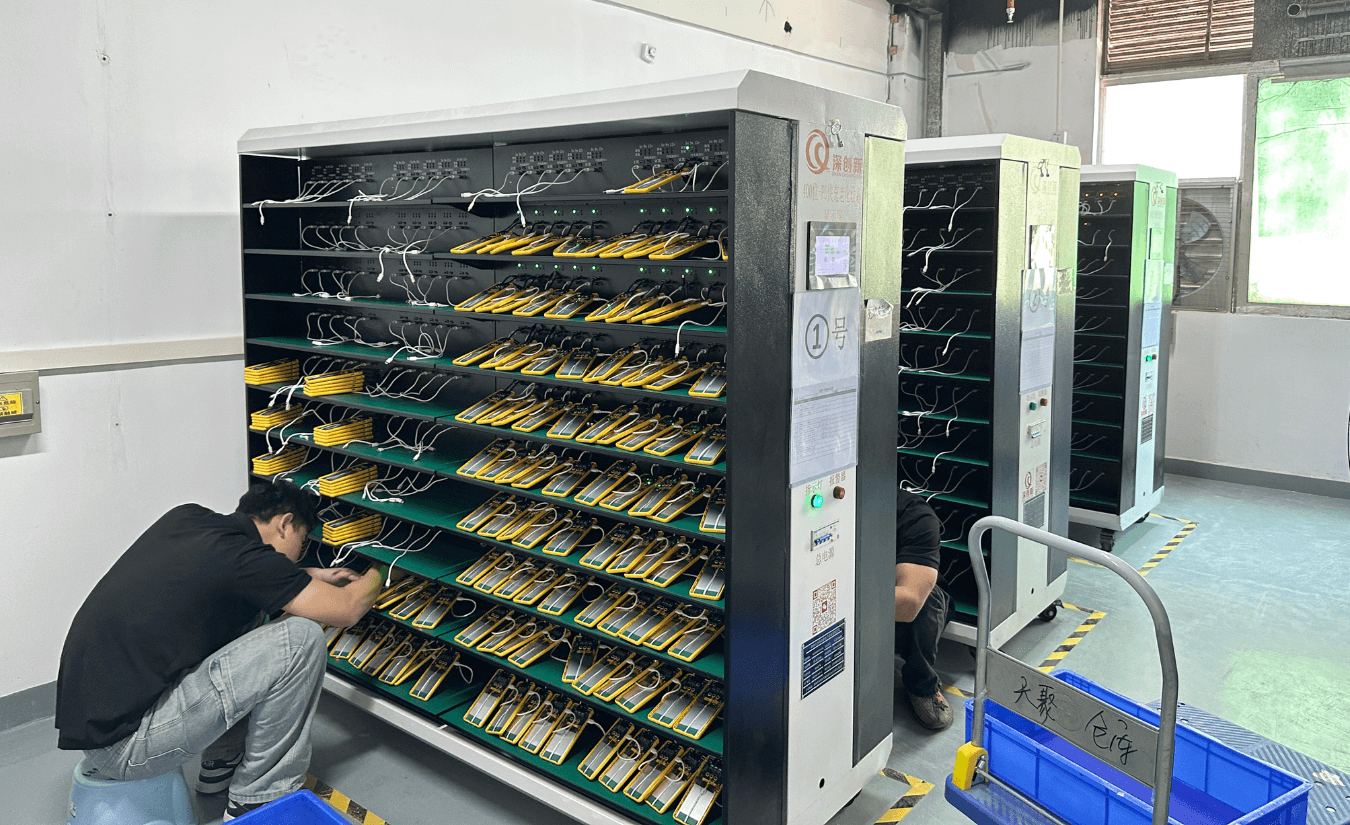

Quality Control in Manufacturing

Incoming Material Inspection

Battery Cell Testing

- Capacity verification

- Voltage testing

- Internal resistance measurement

- Visual inspection

Component Quality Check

- PCB functionality testing

- Connector durability testing

- Cable quality verification

- Housing material inspection

Production Line Testing

During Assembly

- Soldering quality checks

- Function testing at key stages

- Visual inspections

- Electrical safety tests

Final Product Testing

- Full functionality testing

- Safety feature verification

- Cosmetic inspection

- Packaging quality check

Quality Assurance Systems

ISO 9001 Implementation

- Documented procedures

- Regular internal audits

- Continuous improvement

- Customer feedback integration

Statistical Process Control

- Real-time quality monitoring

- Defect rate tracking

- Process capability analysis

- Corrective action procedures

Environmental and Chemical Compliance

RoHS Compliance

Restricted Substances RoHS limits harmful substances in electronics:

- Lead (Pb)

- Mercury (Hg)

- Cadmium (Cd)

- Hexavalent chromium (Cr6+)

- PBB and PBDE flame retardants

Testing Requirements:

- Material composition analysis

- Supplier declarations

- Regular monitoring

- Documentation maintenance

REACH Regulation

Chemical Safety REACH covers chemical substances in products sold in EU.

Compliance Steps:

- Substance identification

- Safety data collection

- Risk assessment

- Registration if required

Country-Specific Requirements

China CCC Certification

Mandatory for Chinese Market CCC (China Compulsory Certification) is required for many electronic products.

Application Process:

- Factory inspection

- Product testing

- Annual surveillance audits

- Certificate maintenance

Japan PSE Certification

Electrical Safety PSE marking is mandatory for electrical products in Japan.

Types of PSE:

- Diamond PSE (specified products)

- Round PSE (non-specified products)

Australia RCM

Regulatory Compliance Mark RCM shows compliance with Australian electromagnetic standards.

Building a Quality Management System

Documentation Requirements

Essential Documents:

- Quality manual

- Process procedures

- Work instructions

- Test protocols

- Inspection checklists

Training and Competence

Staff Training Program:

- Quality awareness training

- Technical skill development

- Standard operating procedures

- Continuous education

Supplier Management

Supplier Quality Control:

- Supplier audits

- Quality agreements

- Incoming inspection

- Performance monitoring

Choosing the Right Testing Lab

Accreditation Requirements

Look for Accredited Labs:

- ISO/IEC 17025 accreditation

- Recognition by target markets

- CNAS, UKAS, or A2LA accreditation

- CB test laboratory status

Evaluation Criteria

Key Selection Factors:

- Technical capabilities

- Market recognition

- Testing timeline

- Cost competitiveness

- Location convenience

Cost Management Strategies

Certification Planning

Budget Allocation:

- Initial certification: 3-5% of first order value

- Annual maintenance: 1-2% of sales

- Market expansion: Plan additional costs

Cost Optimization

Smart Approaches:

- Batch testing for multiple products

- Use CB scheme for multiple markets

- Early planning to avoid rush fees

- Long-term lab partnerships

Quality certification is an investment, not just a cost. It opens markets, builds trust, and protects your business. Work with experienced manufacturers who understand international standards and maintain proper certifications.

Next Steps: Partner with manufacturers who have established quality systems, proper certifications, and proven track records in your target markets. This ensures compliance and reduces time to market.